In modern logistics operations, on-time delivery is no longer a differentiator — it’s an expectation. Meeting this standard requires logistics systems that operate with maximum efficiency, accuracy, and adaptability. For system builders and operators, lighting quality directly influences machine vision performance — and by extension, the reliability of barcode reading, label verification, and object tracking. Inadequate illumination can result in read errors, shipment delays, and missed SLAs, all of which impact customer satisfaction and operational cost. The AL325 Series from Advanced Illumination addresses these challenges head-on, delivering precise, high-intensity lighting engineered to support machine vision in today’s demanding logistics environments.

Built to Adapt to Long Distances and High-Speed Scan Tunnels

One of the most pressing challenges in logistics is achieving uniform, high-intensity illumination across variable working distances. Whether capturing images in confined inspection zones or along extended sorting tunnels, the AL325 delivers consistent, uniform lighting. With lens options such as Narrow (14°) and Medium (25°) beam angles, the AL325 system can be optimized for longer-range imaging typical in logistics operations. These optics provide focused, well-directed light exactly where it’s needed—enhancing image contrast while minimizing unnecessary light spill and energy consumption.

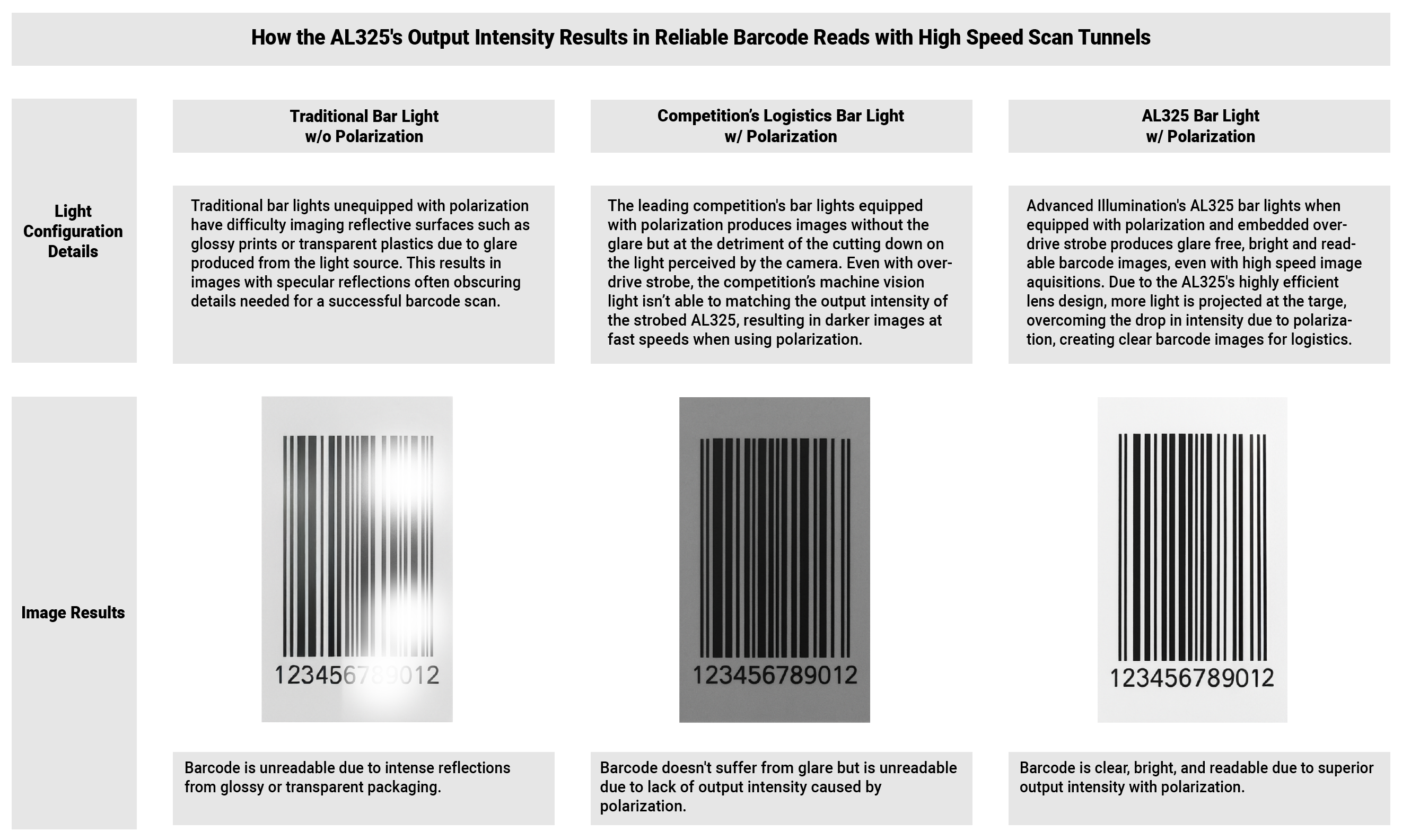

When scanning packages at high speeds, reliable and consistent lighting is essential for maintaining read accuracy. The AL325 delivers best-in-class intensity, supporting high-contrast image capture in fast-moving environments. With stable performance maintained over extended working distances, it enables dependable barcode and label reading in dynamic logistics applications such as scan tunnels, diverters, and high-speed sortation systems—without compromising exposure.

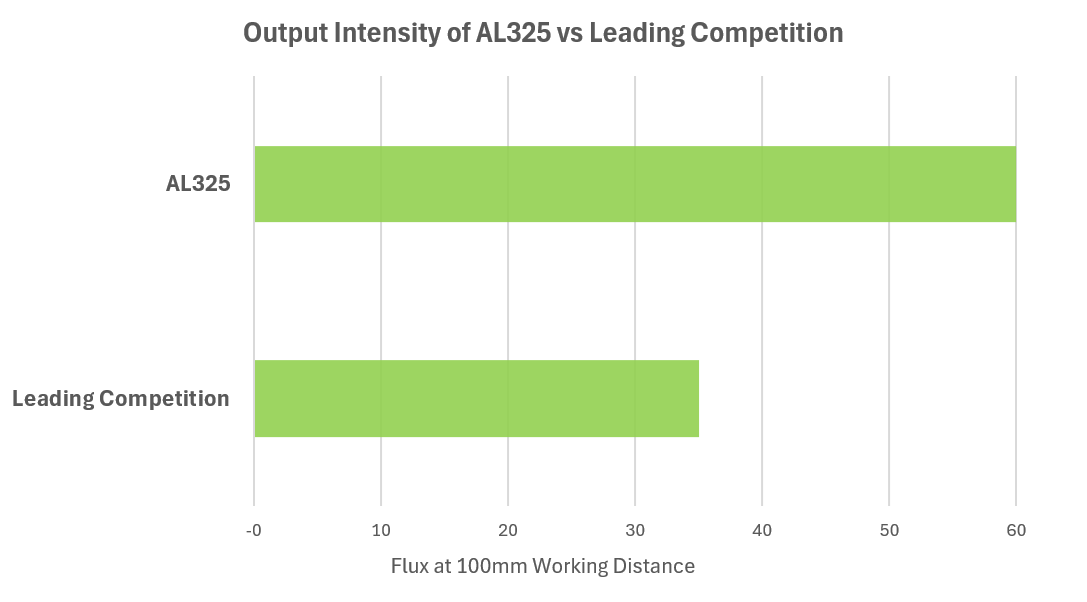

The AL325’s high-output performance and precise beam control at extended distances allows integrators to significantly reduce the number of fixtures required. In typical logistics installations, a single AL325 delivers nearly twice the output of the leading competitor—eliminating the need to double up lights on scan tunnels or conveyor lines. Fewer fixtures mean simpler installations, lower power consumption, and reduced system complexity.

Thanks to its consistent light distribution over extended working ranges, the AL325 ensures uniform illumination across the full field of view. This is essential for high-speed package handling, where inconsistent lighting can lead to barcode misreads, false rejects, or missed tracking events.

The Three Pillars of Logistics Illumination: Intensity, Lens Versatility, and Embedded Control

Professionals in logistics consistently seek three key performance criteria when evaluating machine vision lighting:

1. Intensity that Matches Speed and Scale

Logistics systems depend on lighting that can maintain reliable intensity with every inspection. The AL325 stands out in this regard, delivering nearly twice the intensity of leading alternatives—even when using it’s embedded controller. As shown below, at a 300 mm working distance, the AL325 produces nearly 60 units of flux, compared to just over 35 units from the closest competitor.

2. Lens Options to Address Every Scenario

The AL325 Series offers an unparalleled range of lens configurations—including Narrow, Medium, Wide, Extra Wide, Elliptical, and even Non-Lensed options—so users can tailor beam angles for short-range or long-range imaging. Thanks to field-swappable components, operators can adapt quickly without needing to replace the light. Narrow and Medium lenses, in particular, are optimized for long-distance barcode scanning and field applications.

3. Embedded Control with Overdrive

The AL325’s embedded controller simplifies installation and enables direct access to overdrive strobe functionality. Whether using our EC control option for continuous lighting or the ES option for overdrive strobe and continuous control, the system integrates seamlessly into automated workflows without the need for external lighting control hardware.

Engineered for Seamless Adaptability and Minimal Setup Time

The AL325 is designed to support adaptive configuration during integration and commissioning. Its field-swappable optical components—such as lenses, diffusers, and polarizers—can be adjusted directly in the application environment, enabling teams to fine-tune illumination characteristics in response to real-world imaging conditions. Whether you need to change beam angle, reduce glare, or fine-tune uniformity, the solution is just a component swap away. Advanced Illumination’s modular approach reduces setup time, simplifies on-site adjustments, eliminates the need to order multiple test units, and ensures optimal performance even as operational requirements evolve—without compromising on image quality or performance.

Designed with the Logistics Professional in Mind

Every feature of the AL325 addresses a real-world logistics concern:

| Logistics Objective | AL325 – Advanced Illumination |

| ? Fast Package Delivery | Faster and more reliable reads with high-intensity illumination |

| ? System Reliability | Built with high-quality industrial-grade components for long-term operational continuity |

| ? Read Accuracy | Specialized light conditioning for clear, accurate reads on difficult-to-image package labels |

| ? Increased Throughput | High output and strobe control for fast-moving conveyors |

| ? Adaptability to Your Application | Modular, field-adjustable system configurable during setup for tailored optical performance |

| ? Reduced Operational Costs | Fewer read errors, less hardware requirements, and minimized setup time |

The AL325 Series was developed with the specific performance objectives of logistics environments in mind. From improving read rates on challenging surfaces to supporting high-throughput systems, each design choice reflects real operational priorities. This alignment between product capability and application demand helps ensure that integrators and logistics teams achieve greater reliability, faster deployment, and sustained system efficiency—with consistent performance at every stage.

The Right Light for Evolving Logistics Environments

Whether you’re designing a high-speed scan tunnel, optimizing package tracking, or looking to reduce lighting hardware across your logistics line, the AL325 offers the intensity, configurability, and industrial-grade reliability needed to elevate your system’s performance. With modular optics, embedded control options, and unmatched output at extended distances, it’s a solution built around the realities of logistics operations. Talk to our specialists to explore how the AL325 can support your specific application and help streamline your next machine vision deployment.

See the full specs and explore how the AL325 can transform your application.

Have challenges in your logistics setup? Talk lighting with our experts.