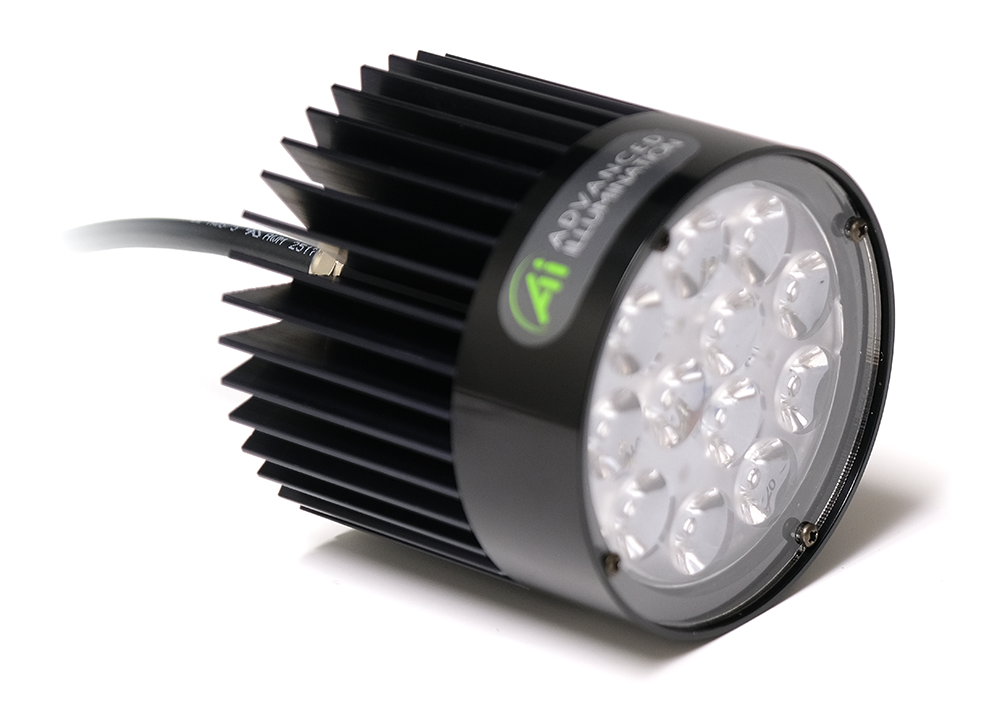

There are several types of inspection spot lights used in machine vision applications. Most inspection spot lights are considered general-purpose illuminators. Spot lights may also be referred to as brick lights or area lights by various suppliers. Inspection spot lights come in a variety of categories including standard, single-point light sources; multi-point light sources; and coaxial light sources, which makes them suitable for a wide variety of machine vision applications.

Single-Point Source Spot Lights

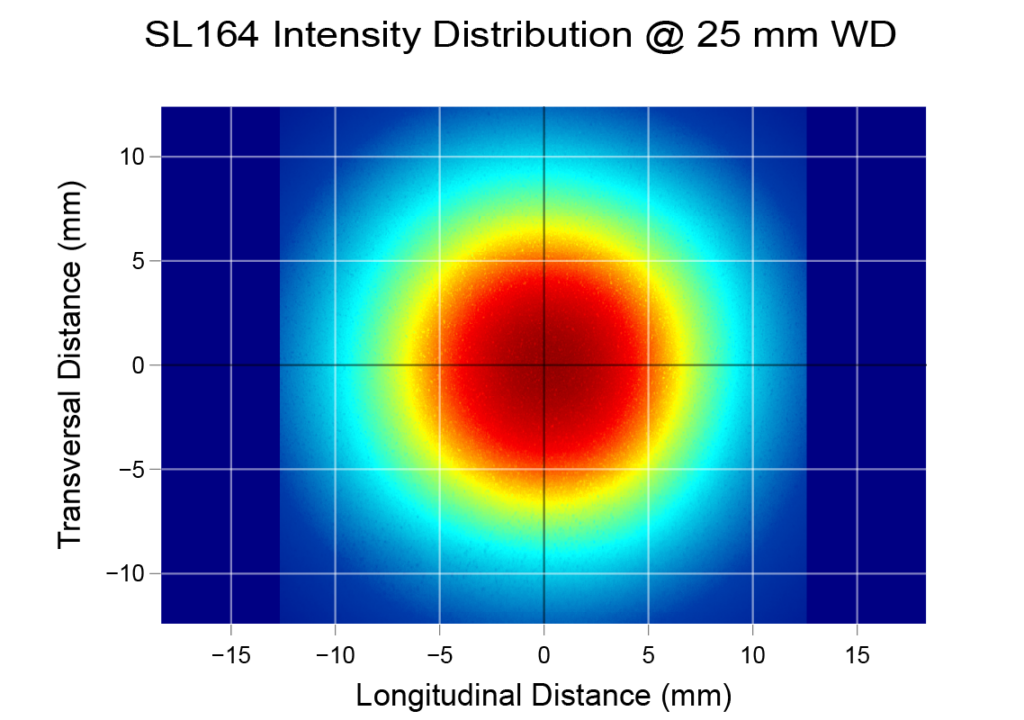

Single-point source spot lights are great for up-close inspection applications that don’t require the light intensity of a multi-point illuminator, which tend to create hot spots in the image when used in applications where the light is close to the object of interest as shown below.

Single-point source spot light provides a uniform intensity distribution up close in comparison to a Multi-point source spot light.

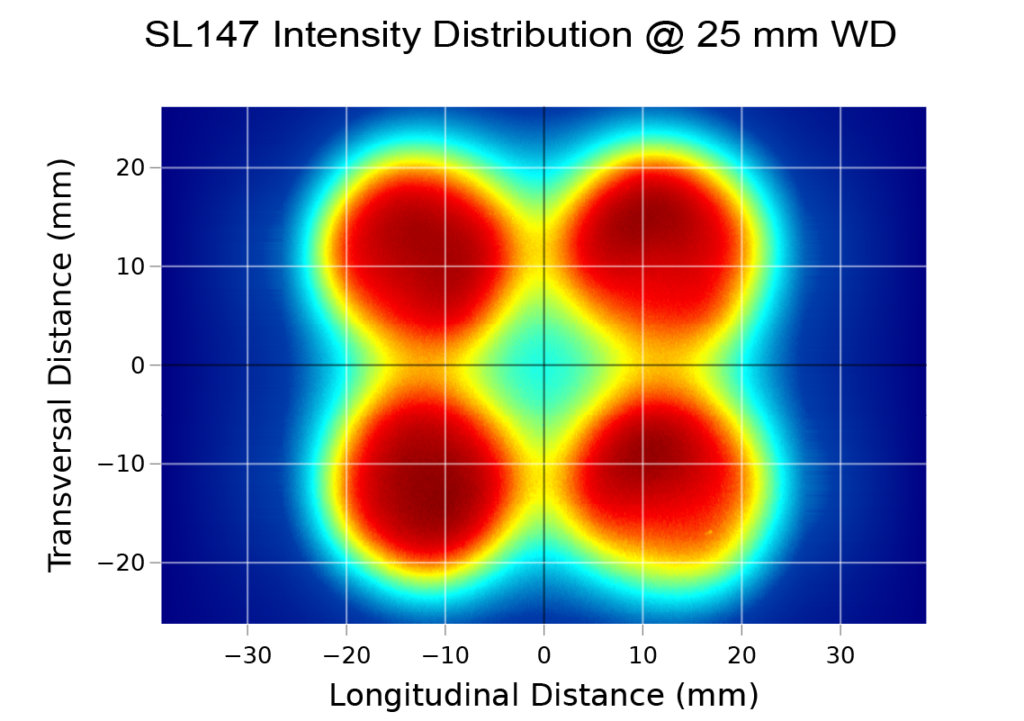

Multi-point source spot light provides a non-uniform intensity distribution at up close working distances do to its four individually focused LEDs causing hot spots.

If the light-camera-part geometry of a machine vision application allows for close enough positioning of the light to the object, a single-point source spot light will typically have more than enough light intensity to properly illuminate the features of interest while not creating problematic hot spots.

Multi-point Source Spot Lights

Multi-point source spot lights, brick lights, or area lights, as many suppliers call them, are suitable for applications that require more light intensity over a larger area than a single point source spot light can provide. With a multitude of focused LEDs, often accompanied with a larger heat sink, multi-point spot lights often outperform single-point in output power, resulting in more intense and widespread illumination over a larger area.

However, if a brick light with an array of lensed LEDs is positioned too closely to an inspection object, for example, there will likely be hot spots from each of those point sources that will show up in the image. To eliminate such hot spots, a heavy diffuser on the brick light window would typically be required.

It is important to keep in mind that diffusers do not exhibit 100% transmissivity. So, depending on the diffuser grade, 15 to 50% of the light intensity may be lost.

Coaxial Spot Lights

A coaxial, or in-line, spot light sends a light source directly into the optical train of an imaging lens. This is often accomplished by using a beamsplitter to merge light that enters through a port on the side of the lens.

Coaxial spot lights are designed to be integrated into such coaxial lens setups. When used for in-line illumination, the light source provides a shadowless image since the light is directly aligned with the lens’s optical axis. Because of this alignment, in-line illumination is well suited for the inspection of specular or semi-specular objects like semiconductors or imaging sensors.

The Benefits of Inspection Spot Lights in Machine Vision Applications

When it comes to general purpose illumination for machine vision applications, the spot light has many benefits and advantages. Spot lights are typically small and compact light sources, which are much less bulky when compared to bar lights and ring lights. As a result, spot lights can fit in very small, tight spaces.

The compact nature of spotlights offers tremendous positioning flexibility, allowing developers to optimize the light-camera-part geometry within a machine vision system. This control over spatial orientation and angularity can be used creatively; for instance, multiple spotlights at different angles can cost-effectively eliminate shadows cast by an object’s features.

This versatility extends to illumination techniques as well. Depending on the angle of incidence of the light, spotlights can be used to create bright field and dark field effects. It is also possible to work from a short to a long distance with inspection spotlights, depending on their size, intensity, and beam spread.

Beyond this flexibility, spotlights are also one of the most affordable general-purpose illumination options for a machine vision system. This cost-effectiveness stems from their simpler design, which involves fewer components than bar lights, ring lights, line lights, and most other machine vision lights.

Interested in selecting the best spot light for your application?

Our machine vision lighting experts are ready to guide you to the right solution!