As poultry consumption continues to expand globally, the OECD-FAO Agricultural Outlook 2025–2034 projects that poultry will account for 62% of the growth in global meat consumption over the next decade, reinforcing its position as the world’s fastest-growing animal protein. Processors are under more pressure to prevent foreign material (FM) from reaching the customer. The hard part is that FM detection happens in harsh washdown conditions, where wet product surfaces reflect light unpredictably and produce glare that can overwhelm the image. In washdown environments, glare from wet poultry surfaces can cause bright spots to oversaturate. If the camera is set to auto-exposure, it may reduce overall exposure to compensate, which can lower contrast in the rest of the image. When illumination also drifts after repeated cleaning, detection models become harder to tune and false rejects can rise.

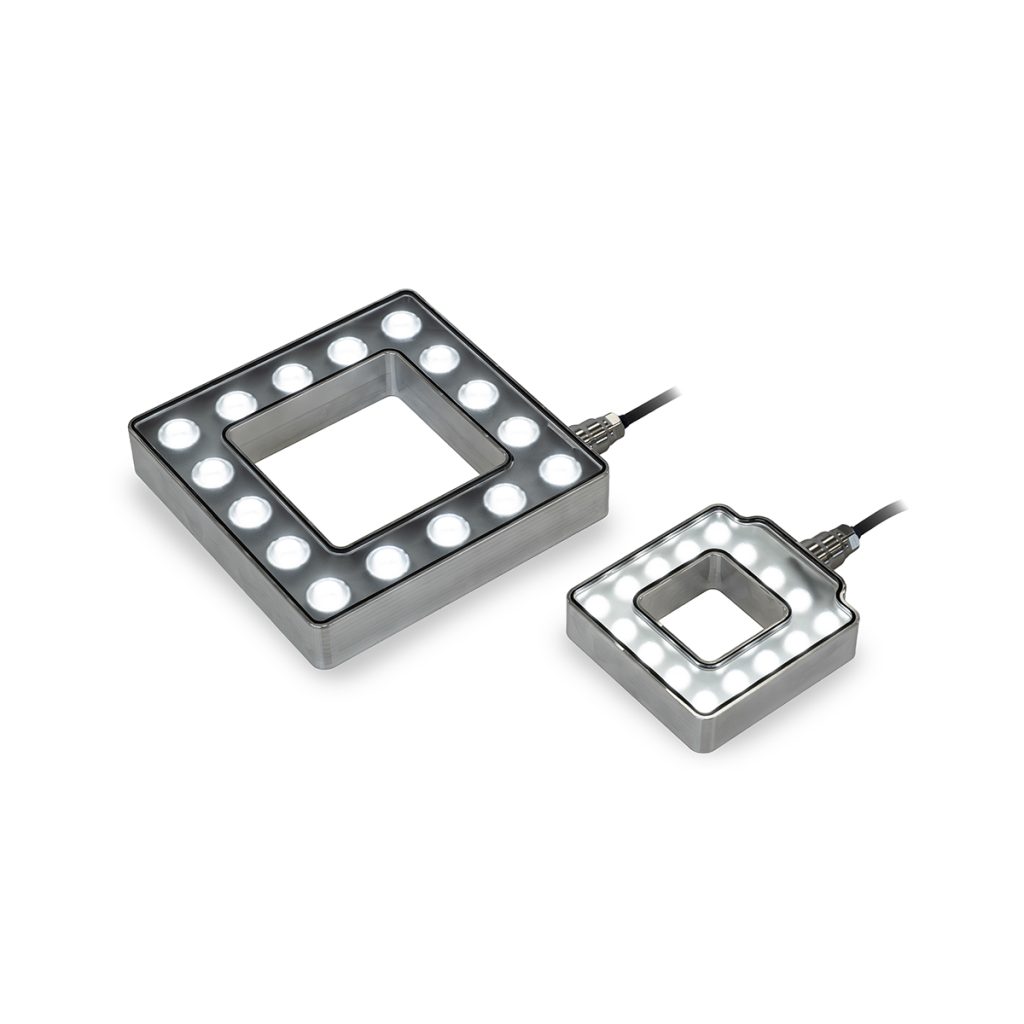

To address this, a poultry processor standardized its final inspection station on the RL322 UltraSeal™ Ring Light to ensure stable, washdown-ready illumination with integrated polarization for glare control, while maintaining throughput and hygiene compliance.

Why RL322 UltraSeal™ for Poultry Final Inspection Modules

1) IP69K-certified hygienic construction for washdown zones

RL322 is engineered for direct integration in Food & Beverage washdown areas:

- 3rd-party IP69K certification for high-pressure, high-temperature cleaning exposure.

- Virtually crevice-free, exposed-fastener-free design to reduce harborage points for bacteria and simplify sanitation.

- Available in Stainless Steel or Anodized Aluminum to suit specific caustic resistance requirements.

2) Native polarization to reduce glare on wet poultry surfaces

Glare is a primary failure point in poultry imaging because surfaces are often wet, glossy, and uneven in washdown environments.

To address this, the RL322 supports a polarization option:

- The RL322 supports a polarization option that helps reduce specular reflections (glare), a common issue on wet, reflective poultry surfaces and when adjusted the geometry and structure of the light source does not remove the glares in washdown environments.

- For glare suppression, Advanced Illumination recommends cross-polarization: a linear polarizer on the light plus a second polarizer (often referred to as the analyser) on the lens, oriented perpendicularly.

Operational impact: cleaner images, reduced highlight saturation, and more consistent detection performance when inspecting reflective product.

3) Quantified output for high-speed imaging

- At 300 mm working distance, a 100 mm white, medium-lensed RL322 delivers up to 34.4 klx (and 107.1 W/m² irradiance) in continuous mode.

For higher line speeds, the RL322 supports overdrive strobing with compatible controllers: up to 10× continuous intensity with an overdrive strobe.

Performance Results

With the RL322 installed, the inspection station maintained stable and repeatable illumination through frequent washdowns, keeping image contrast consistent before and after sanitation cycles. This consistency improved segmentation reliability and strengthened model confidence in foreign material detection at line speed.

The crevice-free design made sanitation faster and more straightforward, saving time during routine washdowns. Polarization reduced reflections on wet product surfaces, minimizing image artifacts that can interfere with accurate classification. As a result, the plant reduced false rejects, maintained throughput, improved sanitation efficiency, and upheld strict hygiene standards at the final inspection stage.

Why OEMs Standardize on RL322 for Poultry Inspection

The RL322 UltraSeal™ integrates IP69K washdown certification, quantified optical output, strobe capability, and polarization support within a hygienic ring light form factor designed for direct installation in poultry processing zones.

For poultry processors, this translates into stable inspection performance across sanitation cycles, predictable image quality under wet surface conditions, and greater confidence in foreign material detection without compromising throughput or hygiene compliance.

Reliable inspection in poultry processing requires illumination that performs as consistently as your production line. The RL322 UltraSeal™ was engineered specifically for harsh washdown environments where glare, sanitation cycles, and high-speed throughput demand stable, repeatable lighting performance.

Interested in learning how our experts can assist you with your machine vision needs?

Click the link below to speak with our application team.