In machine vision, choosing the right wavelength is fundamental. It dictates how light interacts with different materials, which in turn determines the quality of images for automated inspection. Every material has unique ways it absorbs, reflects, and transmits light, all influenced by its makeup and surface. For instance, metals usually reflect most visible light, while certain plastics might absorb some colors and let others pass through. By selecting the correct wavelength, engineers can significantly boost contrast, making specific features or defects much clearer.

Practically, this means using shorter wavelengths like blue light can enhance scattering, which is great for finding tiny surface defects. Conversely, longer wavelengths such as near-infrared (NIR) can penetrate translucent materials, letting us inspect internal structures. Understanding these interactions between wavelength and material is key to creating reliable and efficient inspection processes across various industries, from electronics to food packaging.

Spectral Composition and Color Temperature

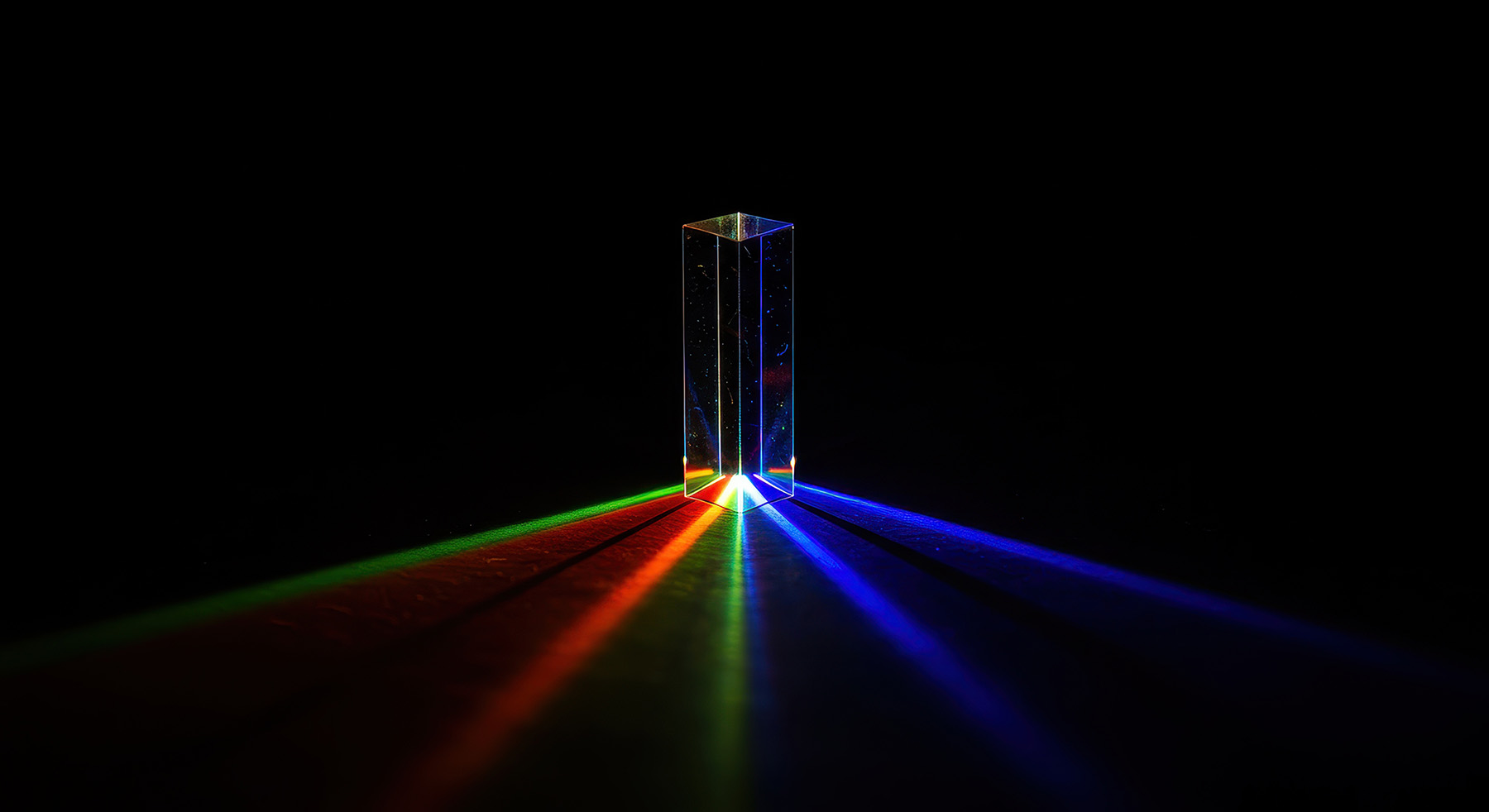

White light contains all visible wavelengths, making it versatile for tasks where multiple colors need to be detected or when general color accuracy is important. However, this broad spectrum can sometimes reduce contrast in inspections that need to isolate specific features. Monochromatic light, on the other hand, emits a very narrow band of light, offering better stability and contrast for precise applications like defect detection or edge profiling.

Engineers often use white light for multicolor checks, like verifying labels. But for tasks needing high repeatability and maximum feature contrast, such as finding scratches on reflective surfaces, monochromatic LEDs are ideal. The choice simply depends on whether your application needs accurate color representation or precise highlighting of specific defects.

Figure 1 – Broad Spectrum White Light vs. Monochromatic Illumination

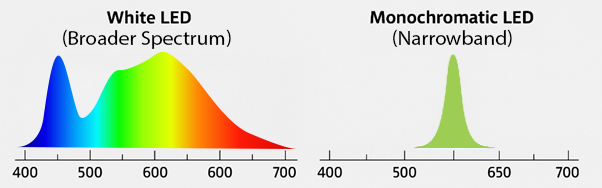

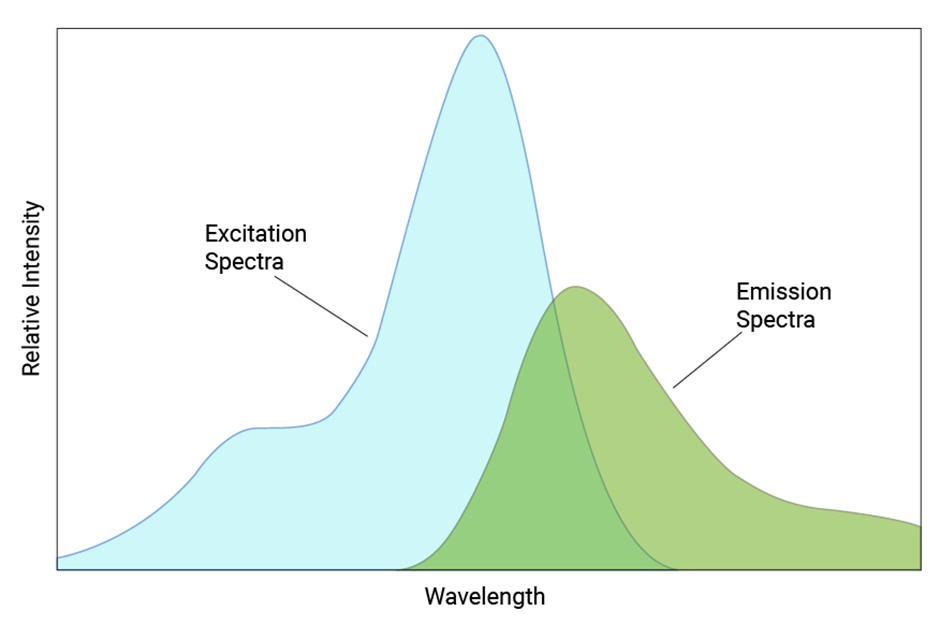

The Color Wheel in Practice

Why do we see colors the way we do? An object’s color is simply the wavelength of light it reflects; all other wavelengths are absorbed. So, a red apple looks red because it reflects red light and absorbs all other colors. The concept of complementary color theory is directly applied in machine vision to optimize lighting contrast. When you light an object with its complementary color, it absorbs more of that light and reflects less, making it appear darker in the image. For example, shining green light on a red object significantly reduces its reflected intensity, making it stand out more against a background.

This principle works even with monochrome cameras, which only measure light intensity, not color itself. Using complementary wavelengths simplifies image segmentation, the process of breaking down an image for easier analysis, and improves the reliability of defect detection. This approach helps ensure consistent performance in automated inspections.

Figure 2 – Color Wheel

Absorption and Reflection

Objects reflect or absorb wavelengths differently based on their color and composition. A black rubber absorbs most visible light, making it tough to inspect under standard lighting. However, using shorter wavelengths like blue light or longer ones like infrared (IR) can reveal surface details or subsurface features that would otherwise be hidden.

Additionally, the surface finish affects how light interacts with an object. Specular surfaces, like polished metal, reflect light in one direction, which can cause glare. Matte surfaces, however, scatter light diffusely. Understanding these behaviors helps engineers design lighting setups that reduce glare and improve defect visibility, leading to clearer images.

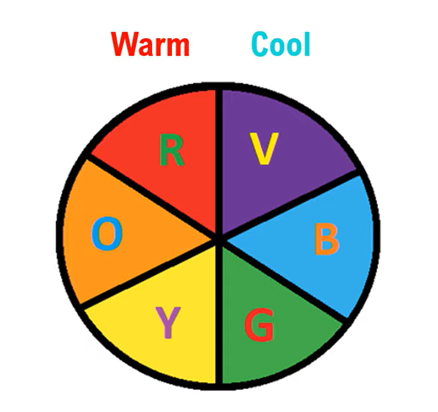

Excitation and Emission (Fluorescence)

Fluorescence occurs when a material absorbs light at a shorter wavelength, often UV, and then emits it at a longer, visible wavelength. This property is widely used for detecting security markings, invisible inks, or fluorescent-labeled contaminants. For instance, UV lighting can reveal security features on banknotes for authentication.

To properly capture fluorescence, you need optical filters that block the excitation light while allowing only the emitted fluorescence to reach the camera sensor. Without these filters, the brighter excitation light can overpower the fainter emitted signal, making it invisible in images. This precise light control is what makes fluorescence imaging so effective.

Figure 3 – Excitation and Emission Spectral Profiles

Transmission

Transmission in machine vision is simply when light passes through a material. This key behavior dictates if we can “see” inside objects. How much light passes through depends on the material’s composition, its thickness, and especially the specific wavelength of light used. For instance, a clear window lets visible light pass, letting us see through it, while a dark fabric blocks it. Understanding this interaction is crucial for advanced inspection.

We use this principle to our advantage in machine vision by selecting wavelengths that make objects appear transparent even if they look opaque to our eyes. This “seeing through” capability is powerful for checking internal components, verifying liquid levels, or finding hidden defects. Imagine a plastic bottle that looks solid: by switching to a specific infrared (IR) wavelength, the camera can suddenly “see” the liquid level inside without opening it.

The secret often lies in the infrared spectrum. While visible light interacts strongly with colors and surface properties, many materials, like certain plastics and liquids, behave differently in IR. Longer infrared wavelengths can penetrate the molecular structure of plastics that appear shiny or opaque in visible light. This is why IR is perfect for inspecting those “shiny bottles”, it lets the vision system look past the container and clearly image the contents. Similarly, a blue-tinted glass might block blue light but transmit red or IR, showing that visible appearance doesn’t dictate transmission across the whole spectrum. This selective transmission by wavelength offers a flexible way to reveal hidden details for inspection.

Figure 4 – Bottle fill level inspection with back lighting, a – 660 nm red, b – 880 nm IR, c – 470 nm blue

Choosing the Ideal Wavelength

Selecting the best wavelength involves understanding several key factors: the material type, its color and texture, the specific defect or feature to be inspected, and the operational environment. Metals, plastics, and glass all interact differently with various wavelengths, impacting how clearly defects or features can be seen. For example, high-speed inspections often need intense, narrowband lighting to freeze motion, while environments with strong ambient light might require filters to isolate the desired wavelength. Ultimately, the right choice balances contrast, penetration (if needed), and the overall reliability of the inspection. This careful consideration is vital for a robust machine vision system.

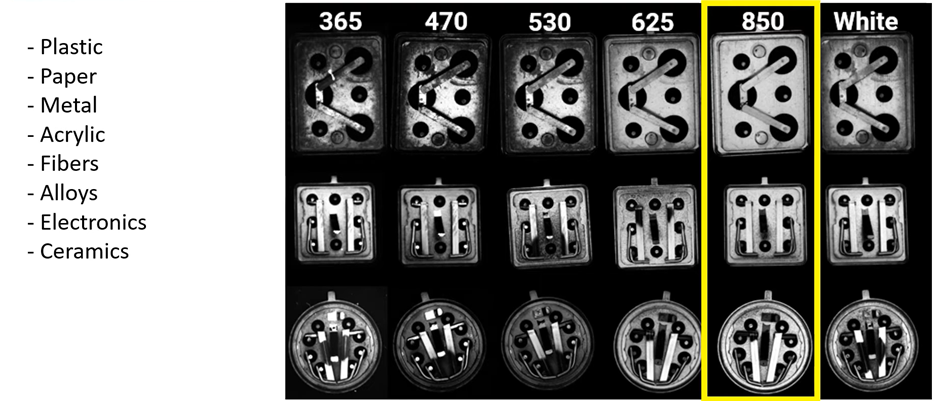

Figure 5 – Three different components tested under multiple wavelengths to determine the optimal illumination. Infrared (850 nm) proved to deliver the best inspection results.

Optical Filters

Filters are crucial for controlling exactly which wavelengths reach the camera sensor. Bandpass filters allow only a specific wavelength range to pass, significantly improving contrast and reducing interference from ambient light. They are especially useful in fluorescence imaging, where they block the excitation light and transmit only the weaker emitted light.

Polarizing filters are excellent for reducing glare from reflective surfaces, which helps improve the visibility of surface defects. By combining the right filters with well-chosen wavelengths, an inspection system can capture clear, analysable images for automated processing, ensuring accurate and consistent results.

Ready to take your lighting strategy further?

Access the Practical Lighting Guide and explore how wavelength selection and lighting techniques can elevate the accuracy and reliability of your machine vision applications.

Talk to one of our specialists to explore the most effective illumination strategies and discover how tailored lighting can enhance performance in your machine vision applications.