Abstract

Overdriving LEDs with short, high-intensity pulses can solve demanding machine vision challenges, such as minimizing

pixel blur during high-speed inspections of singulated or indexed parts. The technique, however, demands a clear grasp of how LEDs behave under such conditions and how different driver and controller architectures deliver the prerequisite precision to overdrive LEDs for maximum performance and reliability.

Good engineering practice always seeks to balance performance and cost. When selecting LED illumination for a machine vision system, it is common to consider how a light’s optical qualities — such as geometry, structure, and wavelength — influence its performance. Some basic understanding of the physical mechanics and control of LEDs, however, can be just as important to optimizing performance, particularly in more demanding applications that benefit from gating or overdriving the device. Moreover, a clear grasp of LED characteristics and behavior can also help extend a device’s reliability and lifetime even when testing the limits of its performance.

To explore this topic, it is helpful to first discuss the distinctions between continuous, gated, and strobed operation of LEDs. Each mode places different demands on individual LEDs, as well as the drivers and controllers powering them. When selecting LED lighting for a vision application, a simple place to begin is to consider the maximum radiant power the light can output on the target while running in constant-on mode — or at a 100% duty cycle. This constant-on maximum current value for the entire light head is determined in part by an LED manufacturer’s product specifications as well as the cooling capability of the light source heatsink. The LED’s limit is determined by some balance between its output power and the incentive to maximize its long-term stability and lifetime. If LEDs can adequately dissipate heat at the diode junction, they can often endure a wide variety of applied currents without harm.

Thus, optimizing control over an LED’s electrical impulses and thermal buildup has a direct impact on the device’s performance, reliability, and lifetime. Controls can also minimize degradation and failure of LED illumination and help ensure it delivers its full return on investment for the user.

This white paper aims to help both machine vision novices and experts navigate the nuanced distinctions between gated and strobed LED operation and understand how LED controls are critical to achieving the optimal balance between performance and reliability in a particular application.

Continuous, Gated, And Strobed Illumination

As with machine vision cameras and sensors, machine vision illumination is defined by its active precision. There is little tolerance for guesswork regarding image capture in most applications. The vision system either isolates and collects the relevant image data — adequately, consistently, and cost-effectively — or it does not. Illumination systems tailored to deliver lighting of a certain geometry, structure, and wavelength can significantly contribute to the success of a machine vision application.

The luminance — a measure of brightness — that lighting provides might seem less nuanced in comparison to these other qualities. In basic machine applications, merely flooding the scene with photons is enough to get the job done. In many machine vision applications, however, simply turning up the lights has limited effect and can actually detract from overall system performance.

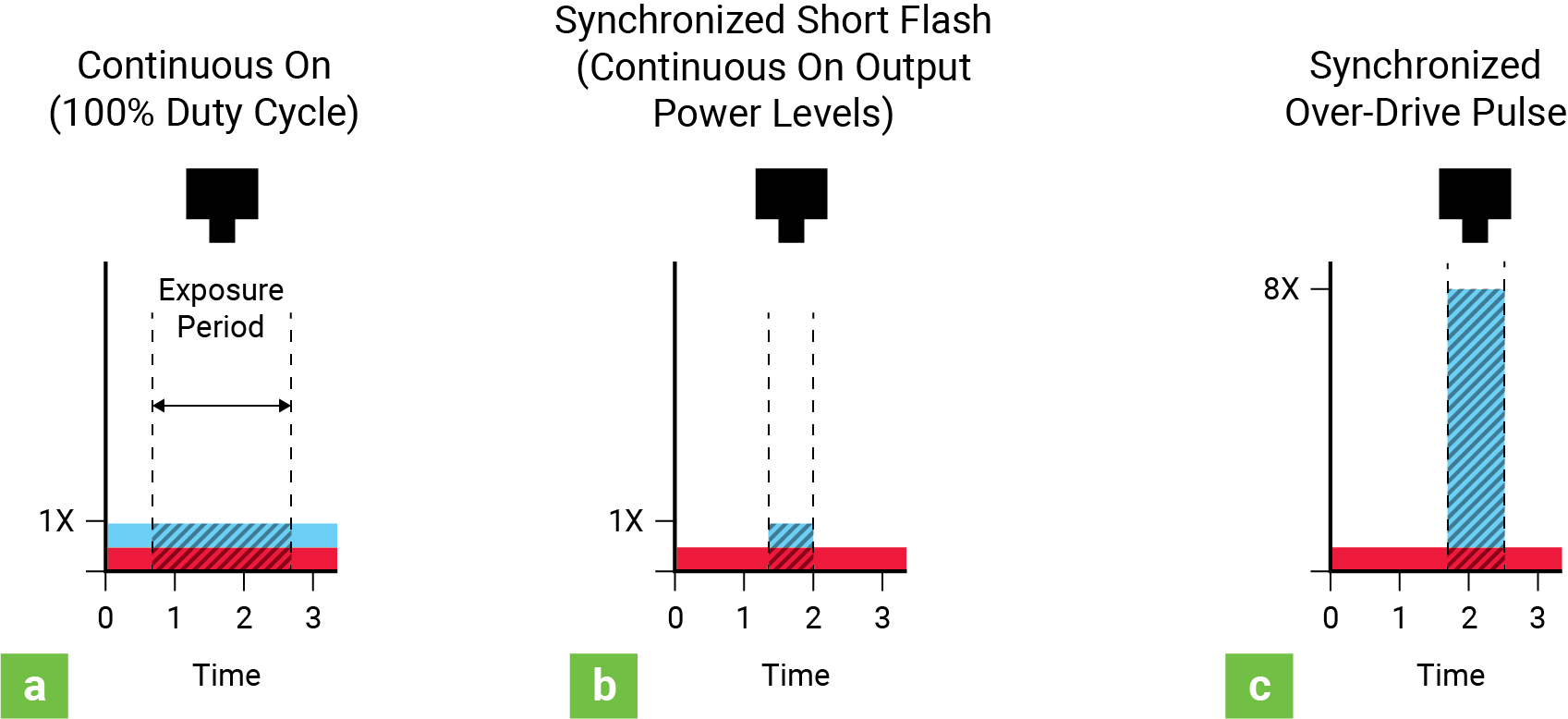

Depending on the application, lighting systems for machine vision most often employ one of three modes of operation: continuous, gated, and strobed (Fig. 1).

Figure 1: Lighting is either (a) constant-on (continuous), (b) flashing at a constant-on current level (gated), or (c) strobing (overdrive). With each lighting mode, you can see a difference in the amount of light collected (hatched area) between signal (blue) and noise (red).

Continuous operation is self-explanatory and places no great demand on LED controls beyond those needed to assign a fixed intensity for the light source. Comparing the distinctions, applications, and benefits of gated and strobe operation, however, requires a deeper discussion, beginning with a definition of terms.

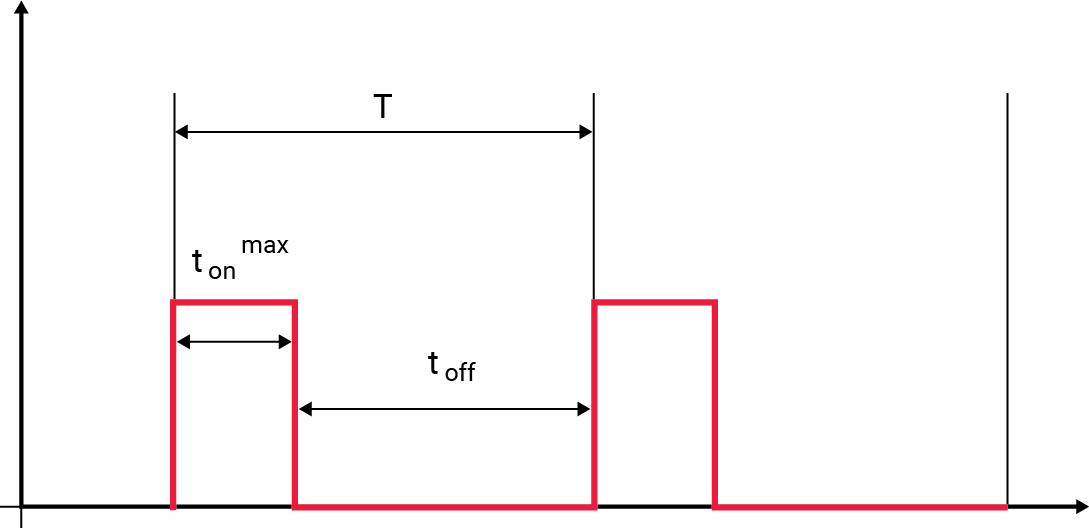

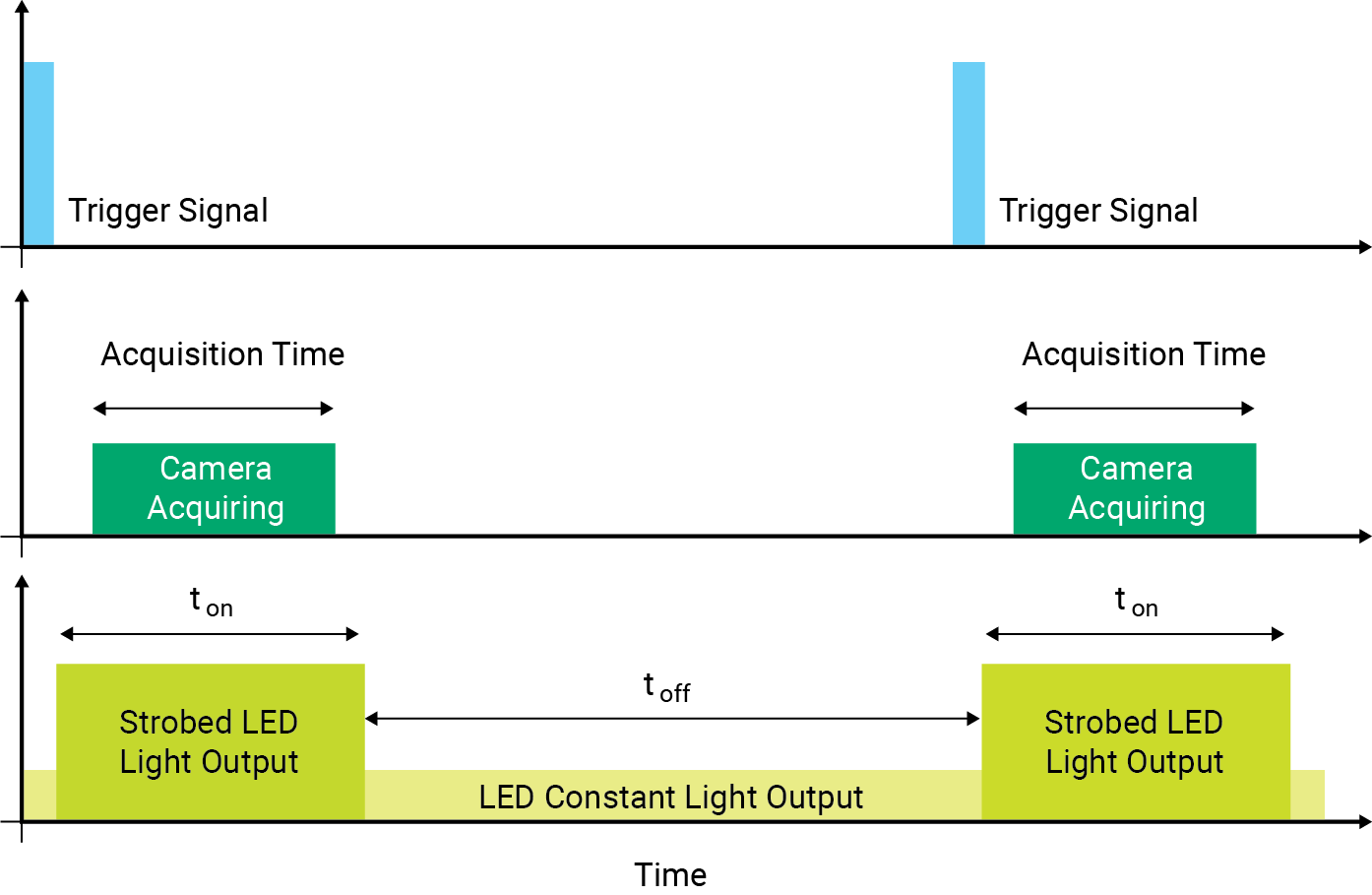

Gated, or gated-continuous illumination, corresponds to conventional strobing techniques used in commercial photography, wherein the power to a continuous light source is repeatedly switched on and off. The ratio of time the light source is on versus off is referred to as duty cycle. Continuous operation has a duty cycle of 100%. A gated light that is switched on for only 100 milliseconds during a 1 second period, however, would have a duty cycle of 10% (Fig 2).

Figure 2: A cycle period is defined by T = ton+toff, where toff is the time the LED light is off and ton is the time the LED is on. Duty cycle is the percentage of the cycle time during which the LEDs are on. It is also possible to express the period T as a cycle frequency in Hertz (Hz), f = 1/T.

Duty cycle is calculated as on-time/(on-time + off-time) x 100.Applied to machine vision lighting, gated operation can better help maintain the thermal equilibrium between a light source’s on/off states, which improves the light’s efficiency and reduces adverse impacts on performance that some LEDs experience from the warm-up effect.

Applied to machine vision, gated illumination is often deployed in multipoint machine vision inspections that must coordinate the output of back- and front-light sources to avoid cross fire between them.

Gated configurations typically emit pulse widths measuring in the tens of milliseconds and, depending on the duty cycle, can deliver higher average output versus continuous operation due to the LED cooldown allowed during “off” periods. A gated LED source employing a 50% duty cycle, for example, might be overdriven 30%–40% harder and still operate at a power dissipation rate equivalent to that when the LED is in continuous mode. The potential result would be 30%–40% brighter output throughout a given exposure time. Though useful in some applications, this technique is more often associated with strobing LEDs.

Strobed lighting is distinguished from gated techniques by some nuanced but important capabilities — particularly where LED sources are concerned. Because they are solid-state semiconductor light sources, LEDs permit more precise control versus xenon lights over the duration and shape of the pulses they emit. More importantly, LEDs can be overdriven to deliver far more intense pulses than what either continuous or gated operations can provide.

Strobe overdriving LED illuminators effectively channels more current through the device at lower duty cycles. In overdrive mode, LED pulse lengths can range from a few milliseconds down to 1 µs, reducing duty cycle from 1% to a fraction of a percent. This allows the LEDs to adequately dissipate the heat between each high-current pulse to avoid damage or loss of performance. This reduction in heat generation also introduces options for simpler lighting designs that require minimal or no heat sinks. It is also beneficial in applications where LEDs are paired with delicate filters or polarizer films that might otherwise be damaged by continuous LED illumination.

More important, however, is the comparatively higher intensity that overdrive pulses can deliver for machine vision setups. The pulse widths for an LED in overdrive can range from 1 microseconds to several milliseconds, but the optimal return on overdrive capacity (for very high levels) typically falls in the 50–500 µs range, assuming the duty cycle remains very low. Depending on duty cycle and other factors, LEDs can be overdriven by 10X drive currents or more and achieve 5X to 10X more intensity than the devices’ typical ratings.

The microsecond pulse widths enabled by strobe overdrive techniques are advantageous for demanding machine vision applications because they minimize both pixel blur during high-speed inspections of singulated or indexed parts and the impact of ambient light. They also can prevent the visual discomfort caused by flashing lights.

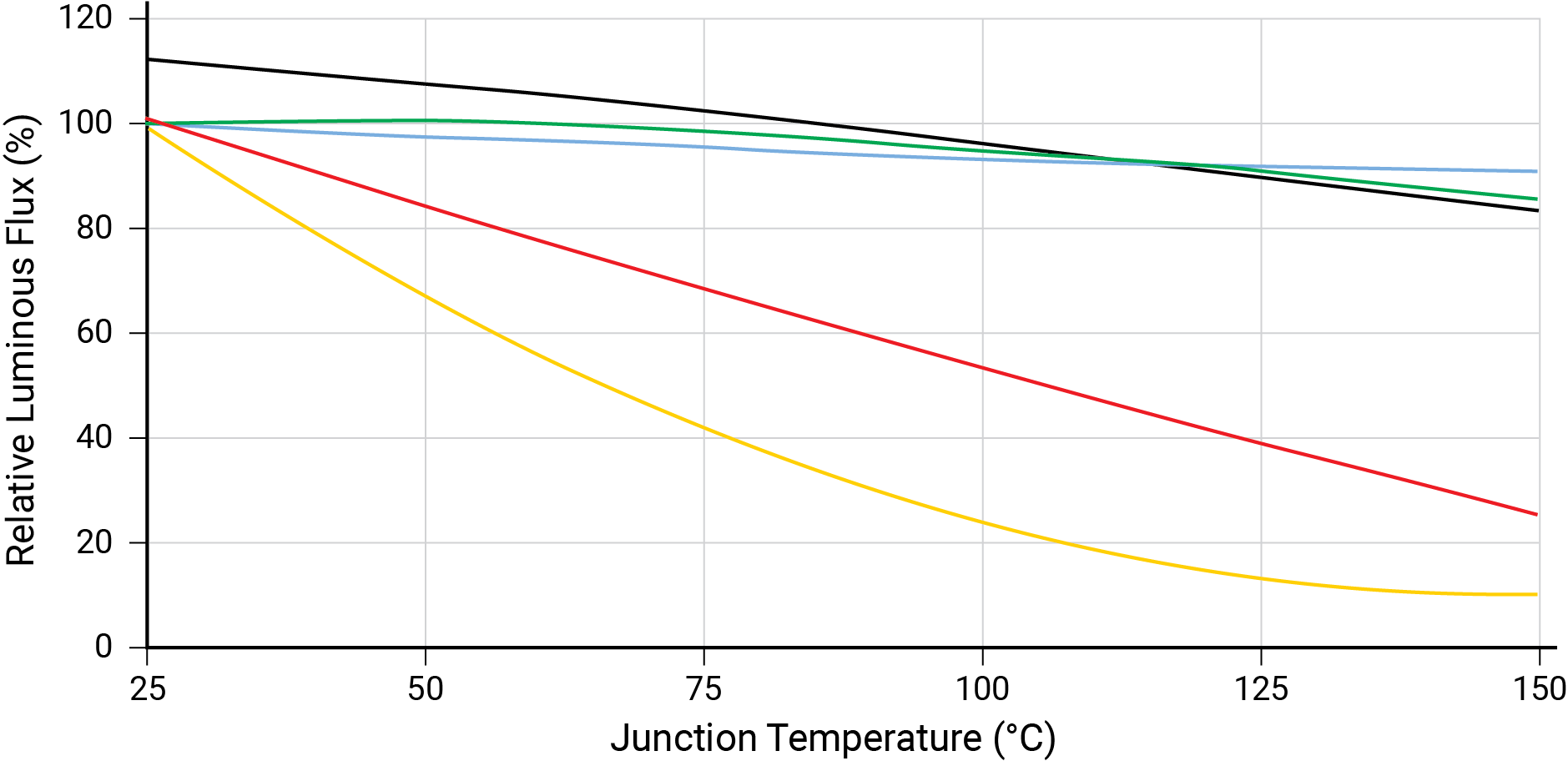

Though low duty cycles can mitigate thermal buildup in the LED device, there are limitations on the output intensities that overdrive strobing can achieve. LEDs begin to lose a percentage of their intensity as the instantaneous junction temperature increases (Fig. 3).

Figure 3: Luminous flux versus junction temperature of visible LEDs – IR, red, orange, and yellow LEDs have different chemical compositions than green, blue, and white. Courtesy of Cree.

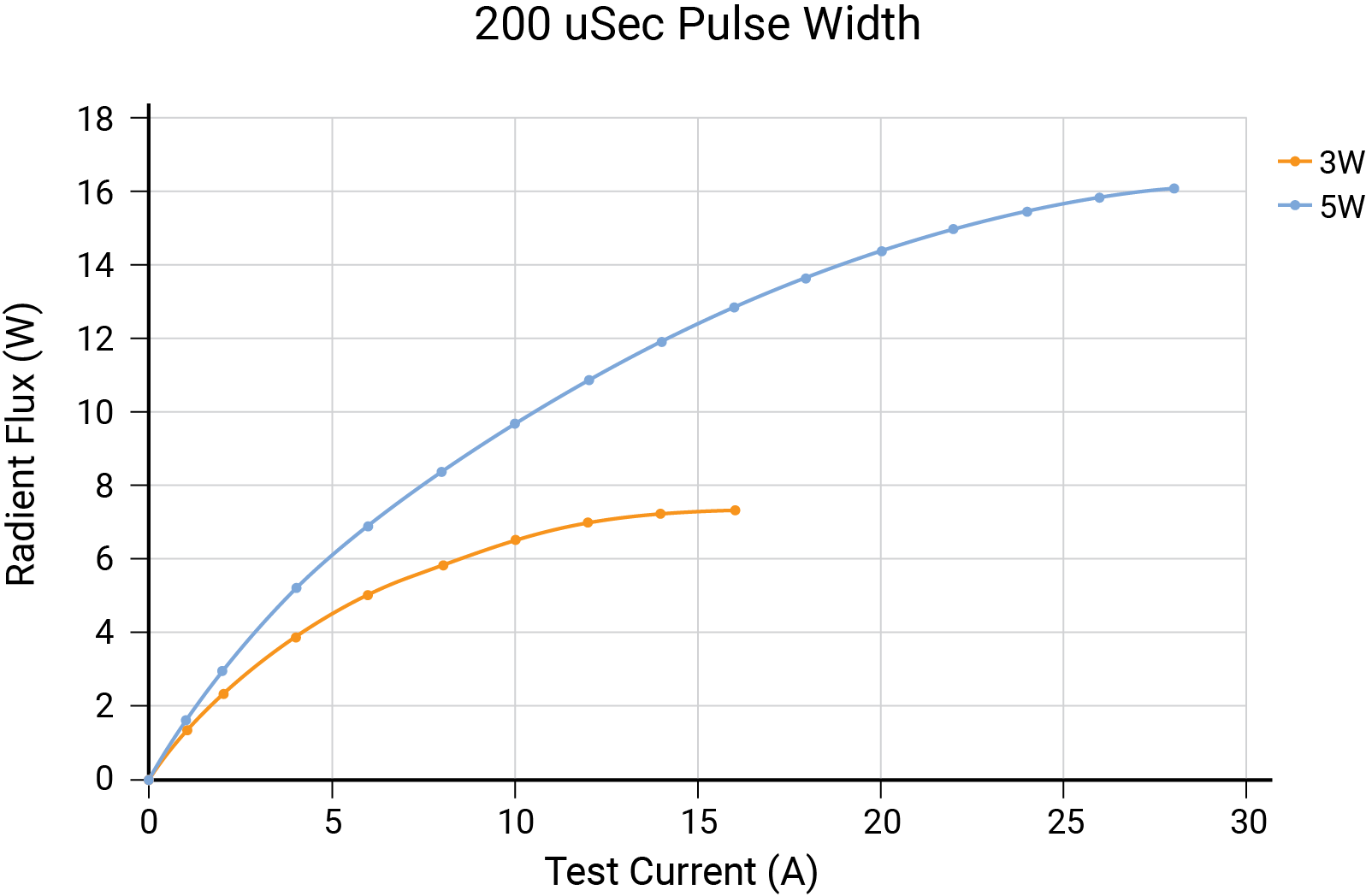

At a certain point, higher input currents simply increase junction temperature without a significant increase in light output — also known as “saturation.” (Fig. 4)

Figure 4: In this strobed output example of a high brightness LED light bar with different LEDs, the Test current is plotted versus the resulting radiant power output at 200 uSec output light on-time. With increasing light output intensity, the response to input current is not linear. At the top of the curve, the increase in input current creates more heat than light output.

In other words, there is a diminishing rate of return in terms of “current in” versus “light out.” A tenfold increase in current, for example, might boost output by only 6X. Also, brighter pulses tend to require longer off periods between each pulse. The solution is to minimize heat generation through lower duty cycles, dissipate excess heat more efficiently, or use some combination of these two methods.

Several other factors also influence how much output an LED can deliver when in strobe overdrive. These include the LED’s type and wavelength, the number of LEDs in an illuminator, the duty cycle, and how well thermal management is handled. The design, architecture, and input power available from a strobing controller is also critical — both to optimize LED output and also ensure overdriving the device will not adversely affect its performance or lifetime. In this respect, a clear understanding of LED lighting controls is central to optimally strobing an LED lighting system for machine vision applications.

Drivers and Controllers

When discussing LED overdrive for machine vision applications, it can be easy to conflate the terms “driver” and “controller.” Typically, a driver is an internal device while a controller is an external one — though it’s important to note that external or embedded designs do exist for both drivers and controllers. (For more on LED controllers, read Advanced Illumination’s white paper: Selecting an Optimal Machine Vision Lighting Controller.)

For this discussion, the key distinction between LED drivers and controllers is based on functionality and hardware. In general, industry nomenclature tends to label anything offering more than basic analog dimming or on/off capabilities as a controller to distinguish its ability to adjust output and strobe capabilities based on user input. Controllers, in this context, often incorporate a driver within the overall architecture and usually allow input via a graphic-user interface (GUI).

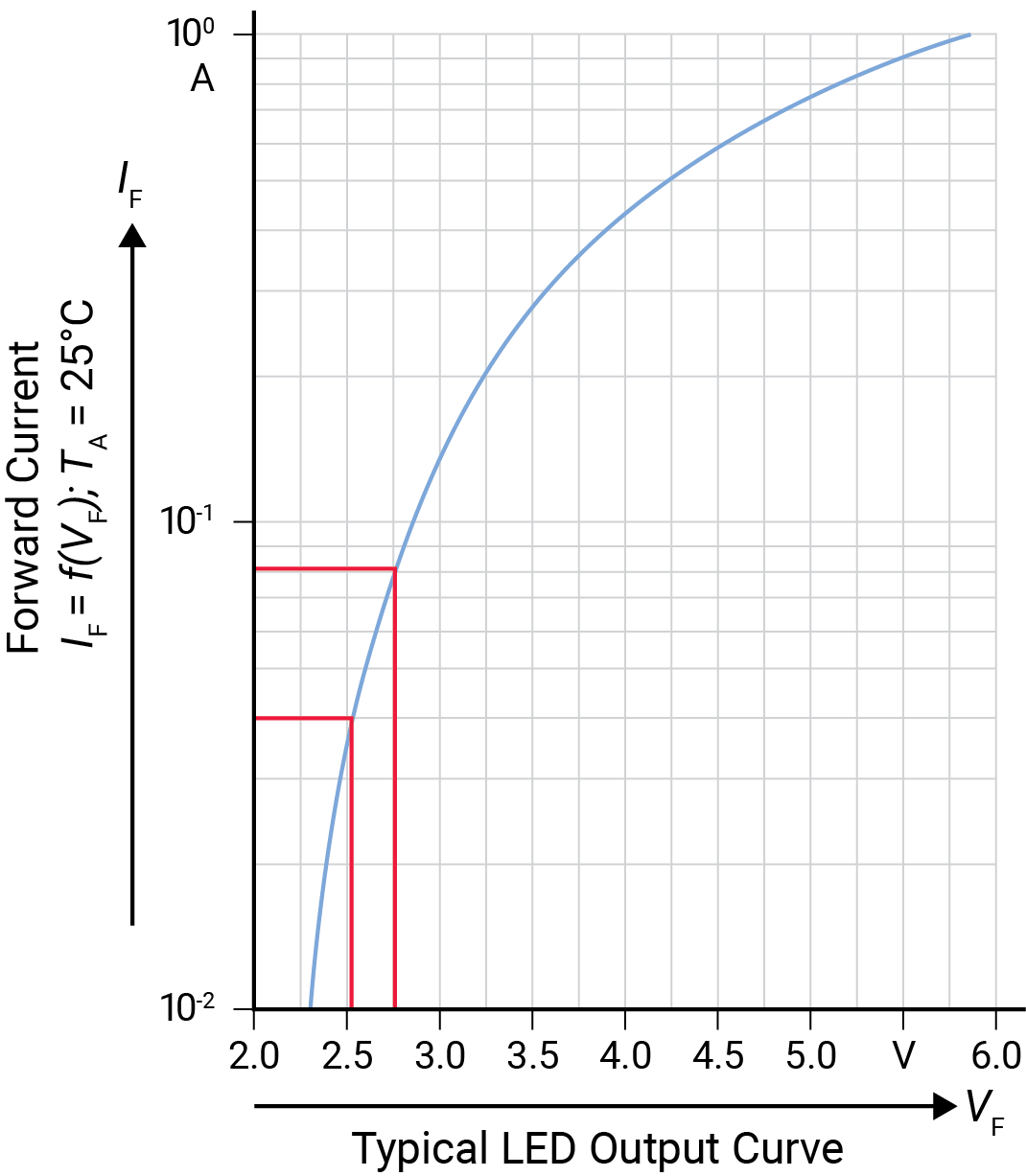

None of this is meant to suggest that proper selection of the right driver is unimportant to overdrive strobing. Overdrive LED strobe operations generally favor controls leveraging constant current drivers over constant voltage mode drivers (Fig. 5).

Figure 5: Even though LED lights are specified as 12V or 24V, their actual light output is determined by the current passing through the semiconductor device. Because of this, LED device manufacturers recommend current control in order to obtain the highest efficiency possible.

This is because even slight changes in voltage can cause substantial shifts in current and potentially damage the LED if it’s not closely regulated. The primary advantage of constant current drivers and controls, however, lies in their comparatively high driving accuracy.

Proper selection and implementation of a strobe controller can contribute significantly to optimizing the duty cycle and thereby improve LED lifetime and performance for machine vision applications. Controllers for gated or low-power LED strobing can employ simple embedded designs, while other controllers are configured to deliver large power output

In general, external controllers tend to be better suited for high-performance overdrive strobing than embedded controllers. Though their externally housed components can increase cost and complexity, they also avoid contributing to heat buildup within the light and allow more room for increased capabilities from larger capacitors, microprocessors, or I/O hardware. External controllers can also leverage GUIs and other software tools, such as the ability to save and load predefined recipes. More to the point, external controllers typically provide more precise control over the intensity and timing of LED overdrive strobe parameters, ultimately optimizing performance beyond the limitations of embedded systems.

GUI-based external controls, for example, can set an LED array’s pulse width by an external trigger input or driver. This is useful in overdrive strobing operations because it allows the LED pulse width to be different in timing and length from the trigger electrical pulse width.

Strobe overdriving LED illuminators maximize output without compromising reliability to deliver outstanding performance in demanding machine vision applications. As with any LED device, good thermal management at the junction is key to balancing its performance and reliability.

Selecting and correctly implementing the right LED control and driver is critical to achieving this balance. But the sophistication of some controllers can further enhance the functionality of an LED lighting system to extract not only the most light but also the most value and ROI from your investment.

The importance of LED characterization

Clearly, no strobe controller can enable an LED to perform beyond its intended limits. Before any controller is selected, LEDs must be thoroughly characterized to determine their maximum performance envelope in order ensure optimal reliably and ROI over the LED’s lifetime.

LED characterization must account for multiple variables that can affect both the initial and long-term performance of an LED. These variables include the device’s sensitivity to ambient temperature, thermal resistance, dynamic resistance to voltage or operating current, and package type, to name a few. The more thoroughly an LED supplier has characterized a device, the more qualified they are to assign the most suitable strobe controller for a particular LED and application.

For more information on how intelligent control electronics can improve your machine vision application, please visit https://advancedillumination.com/ai-technology/the-signatech-advantage/, or reach out to one of our technical experts today to learn how controlled strobe overdrive can improve your machine vision application!

Key Takeaways

- Continuous, gated, and strobed operation of LED lighting for machine vision each seek to extract maximum output without exceeding the thermal or performance limits of the manufacturer’s specifications. If LEDs can adequately dissipate heat at the diode junction, they can often endure a wide variety of applied currents without harm.

- Strobe overdriving LED illuminators effectively channels more current through the device at lower duty cycles to achieve significantly more intense output for short periods while minimizing thermal buildup at the LED junction.

The pulse widths for an LED in overdrive can range from 1 microsecond to 5 milliseconds, but the optimal return on overdrive capacity typically falls in the 50–500 µs range, assuming the duty cycle remains low. Depending on duty cycle and other factors, LEDs can be overdriven by 10X or more above the manufacturer’s limit to provide 5X to 10X the device’s rated output. - There are limitations on the output intensities that overdrive strobing can achieve. At a certain point, higher input currents simply increase junction temperature without a significant increase in light output, leading to a diminishing rate of return in terms of “current in” versus “light out.” Selecting the proper LED controller can create the right optical/thermal balance and offer other beneficial functionalities to maximize the light’s value in a particular application.

- In general, any device offering more than basic analog dimming or on/off capabilities for an LED is typically labeled as a controller. Controllers, in this context, often incorporate a driver within the overall architecture and often allow input via a GUI.

- In general, external controllers tend to be better suited for high-performance overdrive strobing than embedded controllers. Though their externally housed components can increase cost and complexity, they also avoid contributing to heat buildup within the light and accommodate increased capabilities from larger capacitors.

Interested in strobe overdrive for your machine vision application?

Click the link below to talk with our application experts.